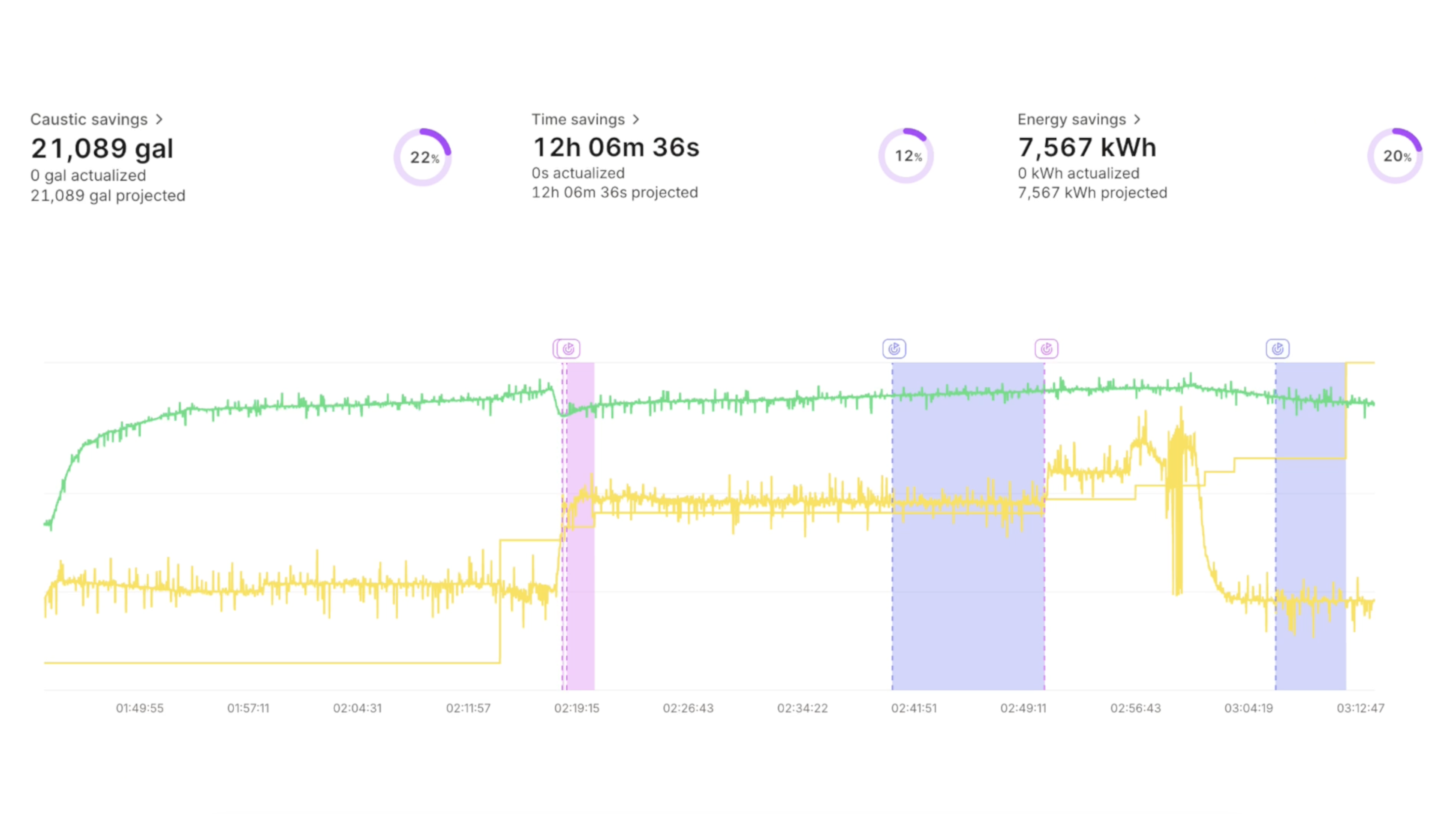

Try the #1 CIP Savings Finder helping Top 10 F&B brands capture $10,000+ in savings with zero commitment

Now you can leverage our expertise, backed by thousands of Clean-in-Place runs. With a few simple data points, we can identify optimization areas for your specific CIP system.

Enterprise-grade analysis • Zero upfront cost • No commitment required

Trusted by Leading Manufacturers

With three simple steps — all governed by strict SOC 2 Type II compliance. Watch the video to see how it works.

Fill in background information on the specific CIP loop you want us to analyze.

Upload a data trendline of a few CIP runs from that loop.

Submit the information for our analysis.

Watch this quick video to learn how Laminar optimizes your CIP process.

Cut CIP time by hours. Get real answers in 24 hours—not weeks.

Enterprise-grade analysis. Zero upfront cost.